Introduction to Shaft Grounding Systems

Shaft grounding systems work as protective systems that ensure the smooth running of electrical motors and generators to prevent equipment failure and or disruption of service. These systems protect the bearings and other important parts from being burnt through electrical discharge. At the heart of effective shaft grounding systems are two key components: slip rings and carbon brushes. More to the point, this article focuses on ways of achieving the best quality of slip rings and carbon brushes.

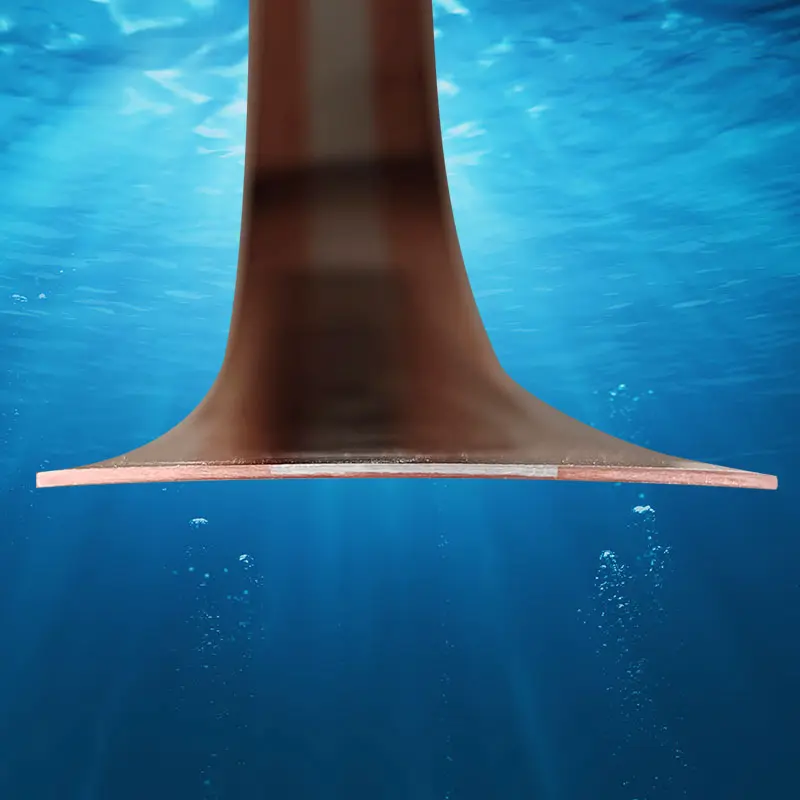

The RoleofSlip Rings

Slip rings are the electromagnetic current collectors and voltage transmitters in electromechanical systems that are used to connect a fixed and a rotating structure. These are crucial for any application that would see a rotating structure need to have electrical connection. In shaft grounding systems, slip rings are used to transfer the electrical currents, which are involved in the grounding systems so that the machinery’s shaft can freely rotate without disconnecting or losing connection with the grounding system.

High quality slip rings toward extremely harsh conditions and rigorous usage of the equipment on which it has been installed. They must supply a stable course through which electronic currents can flow without much hassle and at the same time withstand the forces that would wear them out. This helps to keep the slip rings as durable and also gives minimal chances of frequent maintenance. When selecting slip rings, it is right to decide on the ones made of non-corroding material; their increased degree of construction also increases the shaft grounding system’s durability and workability.

Importance ofCarbonBrushes

Carbon brushes combined with slip rings satisfactorily complement a shaft grounding framework. It’s these brushes that transmit current between several fixed wires and the various component parts which are in motion. The nature of the material used to make the carbon brushes should have high conductivity and at the same time resistant to constant use because it could easily wear out due to its function.

The content carbon brushes are designed to offer quality, low electrical contact resistance, and long-lasting life performance. When designing them, they need to take into account such aspects as the operating speed of the machinery, the conditions in which the equipment will be used, as well as the electrical loads which will come across. The outcome of employing marginal carbon brushes is costly maintenance, more frequent replacement or even serious machinery breakdowns.

Checking forComplianceand Efficiency

Slip rings and carbon brushes complement each other in providing balanced operation of the shaft grounding systems. To be more precise, one of these two components must be designed to be more dominant than the other, while the other must be complimentary and possess the desired properties that will enable efficient electrical continuity and consistent minimal amount of maintenance. As a result, it is safer to order slip rings and carbon brushes from the producers to consult with them about the proper connection of grounding systems.

It is also important so that the machine can be checked occasionally hence finding signs of degradation during early phases. This involves the examination of carbon dust deposition, asymmetric distribution of brushes or abrasion on the slip ring. These problems, therefore, need to be corrected as soon as possible so as to maintain performance to the expected levels and to avoid cases of costly breakdowns.

The significance of on high quality elements

There are several important benefits to be derived: Investing in high quality slip rings and carbon brushes. First, they give constant and dependable electrical connections, which is essential for reliable and reliable revolving applications. They shield and preserve the effectiveness of momentous components and are responsible for the increased existence of the whole system by avoiding unsystematic electric discharges.

Second, they contribute to the prevention of frequent service and correction of substandard components. That way the proper and long lasting parts are being used reducing wear and tear so they do not have to be replaced or repaired always. Not only does it save time and money it also became possible to make sure that some vital operations can indeed go on uninterrupted.

Third, quality of the slip rings and carbon brushes plays a major role in enhancing efficiency of the system. Lowering resistance-electrical and networking-creates enhanced energy efficiency that is pro-performance and cost effective in the long run.

Conclusion

When it comes to shaft grounding systems, therefore, only the best of slip rings and carbon brushes will suffice. These components are critical elements of operating a rotating machinery in a dependable and high performing manner. One way of improving the lifespan of equipment, while also reducing downtime and maintenance expenses, is substituting slip rings and carbon brushes with cost-effective solutions that would be less maintenance-heavy.

Also, the competitive ability of the shaft grounding systems in the long run is going to be better if one has invested in better components. With growing technology, new ways to more efficiently create slip rings and carbon brushes are going to be developed.

EN

EN